Drilling Tools For Top Drive For Well Complection

The drilling tools for top drive can directly rotate the drill string directly from the upper part of the derrick space and feed it down along the special guide rail to complete the drill string rotary drilling, circulating drilling fluid, connecting single roots, making and unloading, and undercutting. Drilling machinery and equipment for drilling operations.

The drilling tools for top drive include top drive floating cushion sub, ibop for top drive, mechanical casing running tool, hydraulic casing running tool and hydraulic casing running tool.

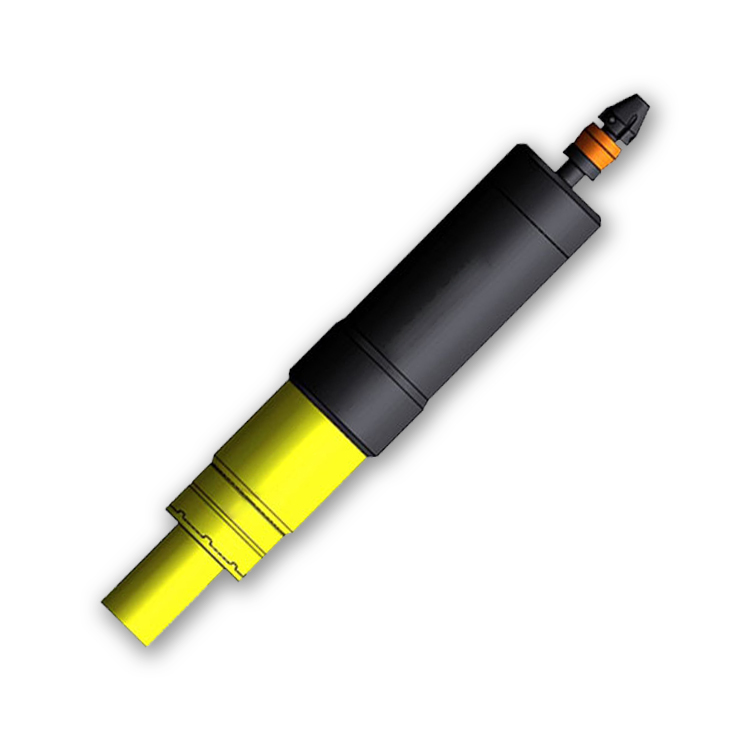

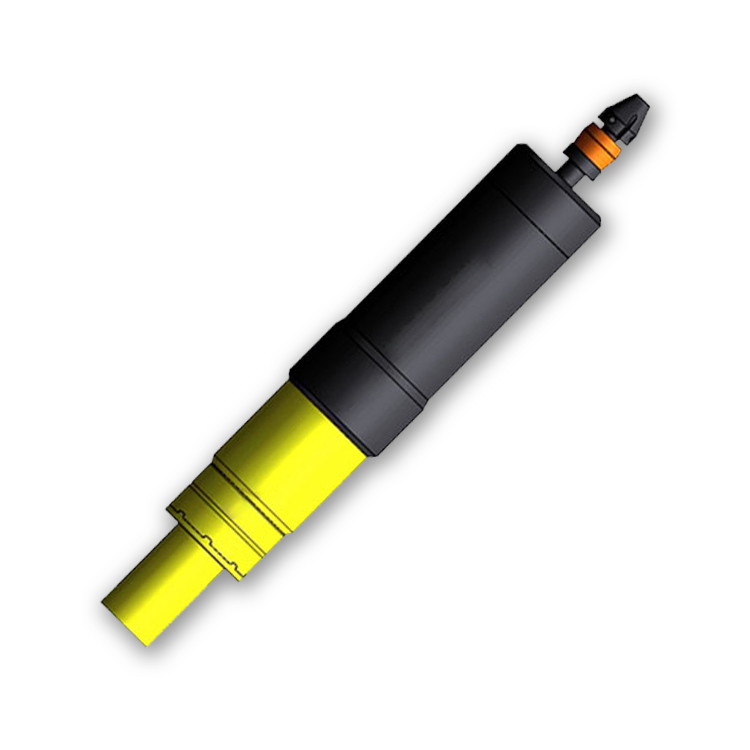

1. Top drive floating cushion sub:

Top drive floating cushion sub is an important tool in drilling operation. It is suit to the drilling process in oil,gas and geological exploration. Mainly used in inclined and vertical drilling operation and drilling rig vertical drilling operation. It can increase the service life of bearing and gear in top drive rotary box.

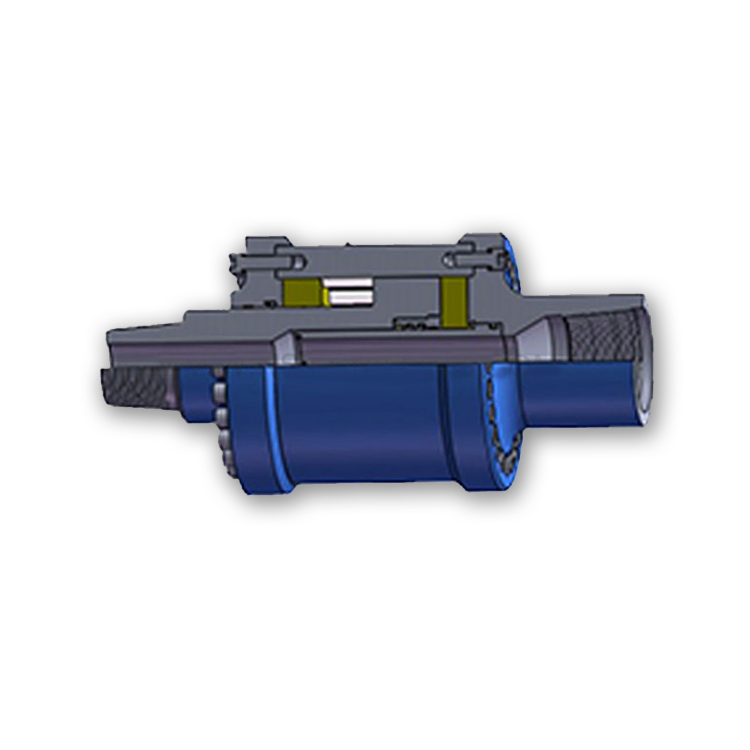

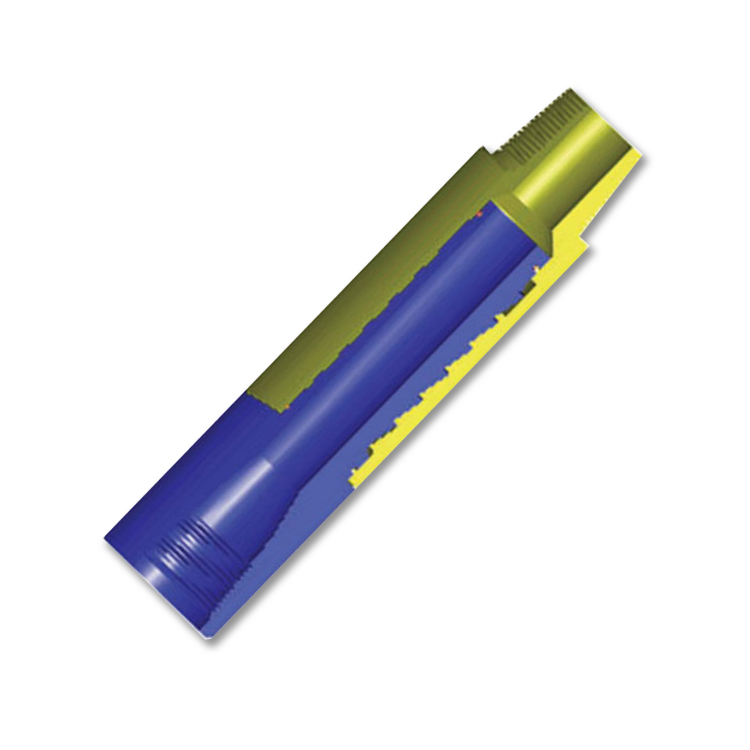

2. IBOP for top drive:

IBOP for top drive can be divitied into Upper IBOP and Lower IBOP. They are control valves which are used with the top drive drilling device. The IBOP adopts high reliable metal seal. So it can bear high pressure upward and downward. The working pressure can be achieved 10000 psi or 15000psi. When well kick occurring,the upper IBOP can be closed by remote controlled,but the lower IBOP will be closed manually. Actuator for top drive is a subsidiary body which controls open and close of Upper IBOP. It works with other accessories of the rig,so as to control openning and closing of Upper IBOP on any height of derrick driller console. Both the valve body cavity and accessories have special anticorrosive processing,so that prolong the service life.

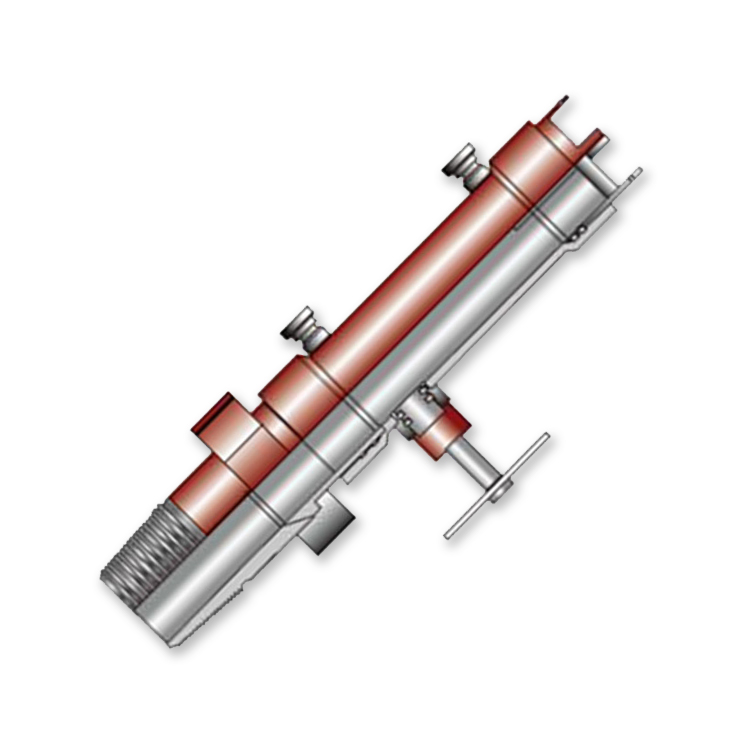

3. Mechanical casing runnning tool:

Casing runnning system is a new technology of runnning in casing ,in casing operations,the most important thing is to run the casing into the bottom of the well safely. Our company's external grip machanical casing running tool can complete the work of makeup,lift and lower,rotation,circulation,etc. It maximum ensures that the casing can be run into the bottom of the well,which greatly improves the success rate,safety and efficiency of runninng in casing operation.

4. Hydraulic casing runnning tool(Internal Grip):

Casing runnning tool is a new technology for runnning in casing. We developed the more safe and efficient internal grip casing running tool to break the limitation of normal running casing operation. This technology can take full advantages of top drive drilling,make the casing string roatating,lift and circulating mud at the same time when running in casing,it maximum insure and casing could be running to the well bottom normally,improve the success rate,safety and efficiency of casing running observably.

5. Hydraulic casing runnning tool(External Grip):

The external hydraulic casing runnning tool is used for casing running opeation with the top drive drilling system. It is connected with the top drive main mandrel or the compensator .