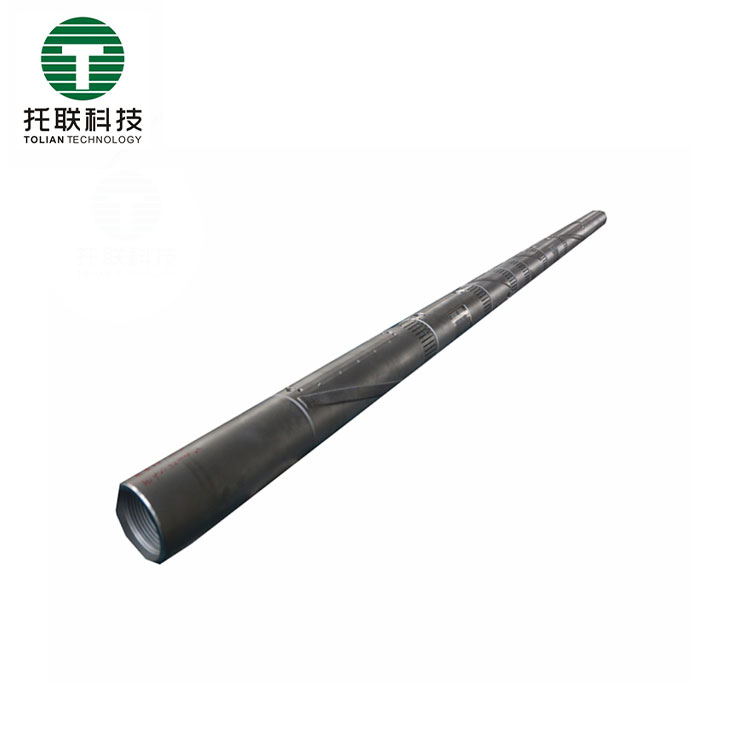

Lwd Drill Collar

Brand : Tolian

Product origin : Liaoning

Delivery time : 15days

Supply capacity : 1pcs/week

Lwd Drill Collar is made of nonmagnetic material to monitor whether the borehole goes following the designed path to insure of accurate measurement.

Tolian workshop is equiped with the up to date precision machining equipments like CNC thread lathe, deep hole boring machine, roller burnishing equipment, deep hole honing machine, milling machine etc. Shenlong has the capability to provide the customers worldwide with the precision machining tools.

Tolian's MWD PARTS include MWD subs (made from Chromium Manganese Austenitic stainless steel ), compressive stress resistance pipe (made from XM-19 stainless steel) for installing MWD impulser inside and amongst others.

Tolian's MWD PARTS have been widely used by domestic and international directional drilling companies.

company strength

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning,Milling ,boring and drilling | |

| CNC drilling deep hole and slender hole | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, gun drill, deep hole boring and driling machine, plano milling and boring machine |

| Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm | |

| CNC machining center range: four axis linkage | |

| Gun drill range: Dia3mm--12mm length: 3-5M | |

| Deep hole boring and drilling range: length:6m dia 200mm | |

| plano boring and milling range: stoke 2m*4m | |

| Cerificate | API ,ISO |