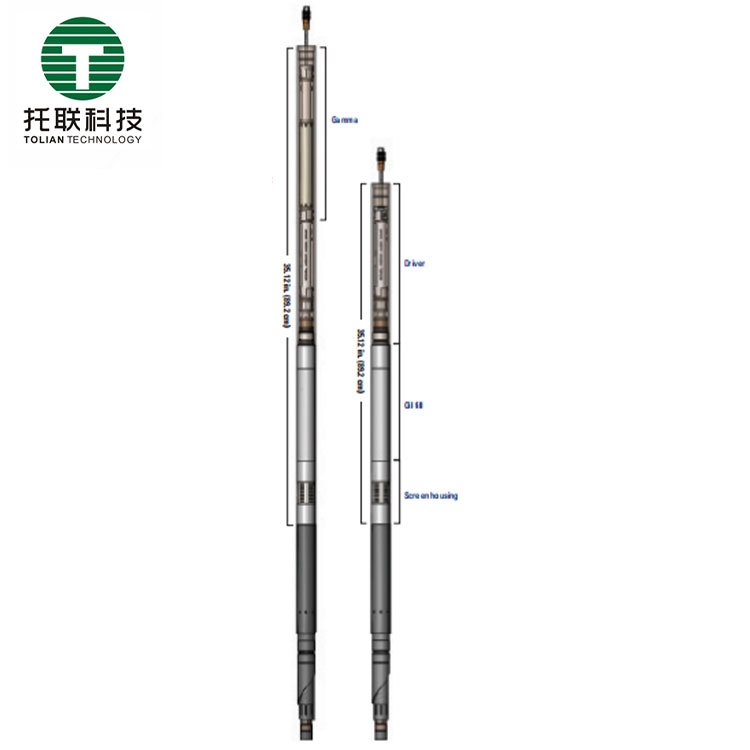

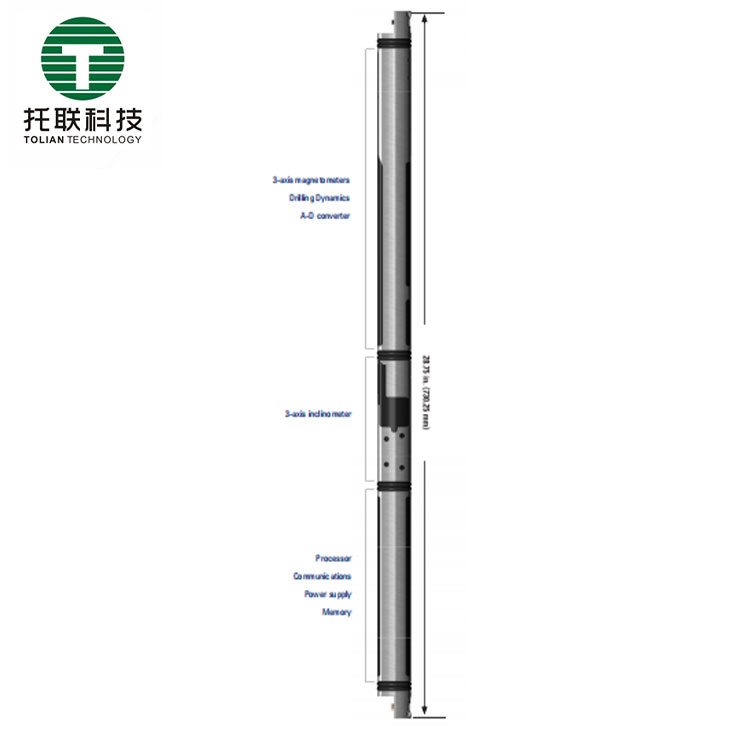

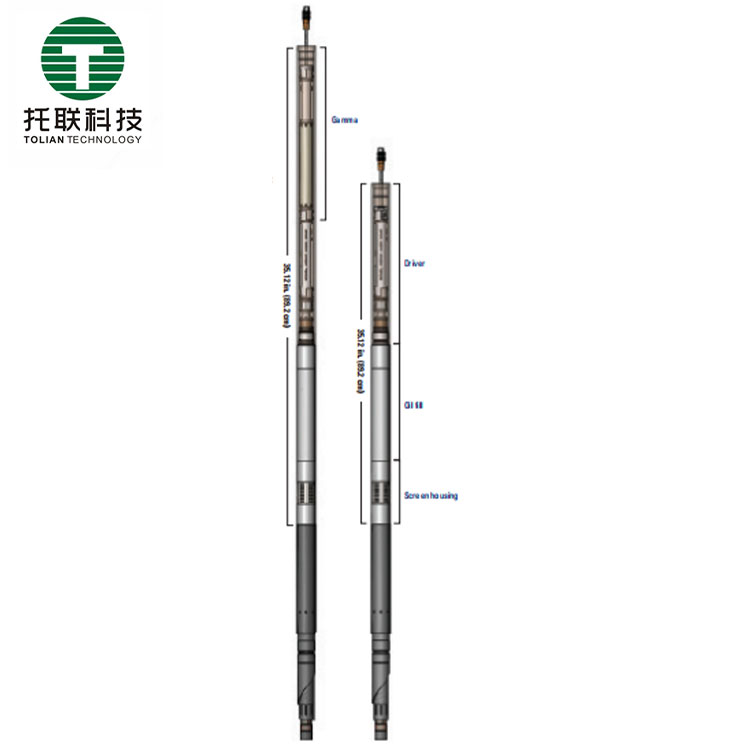

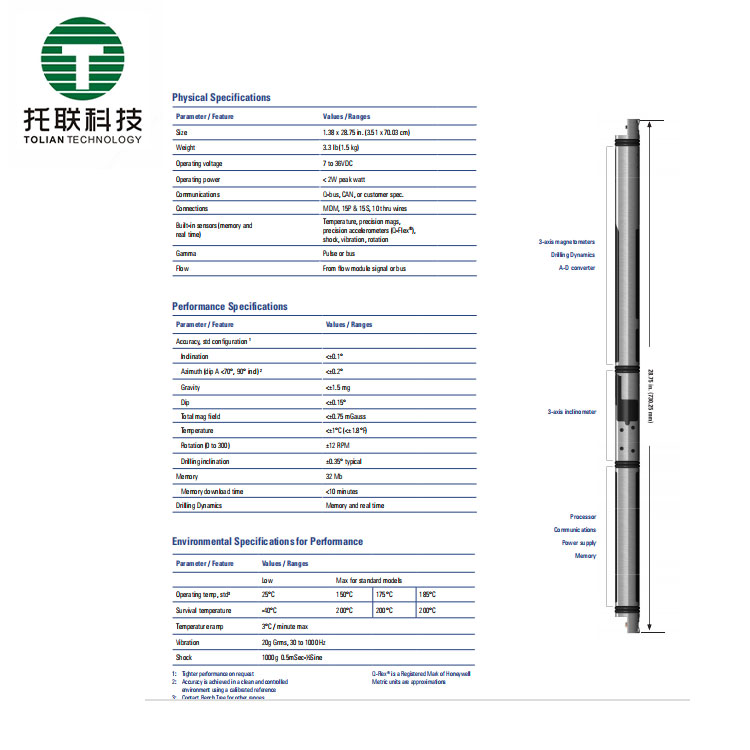

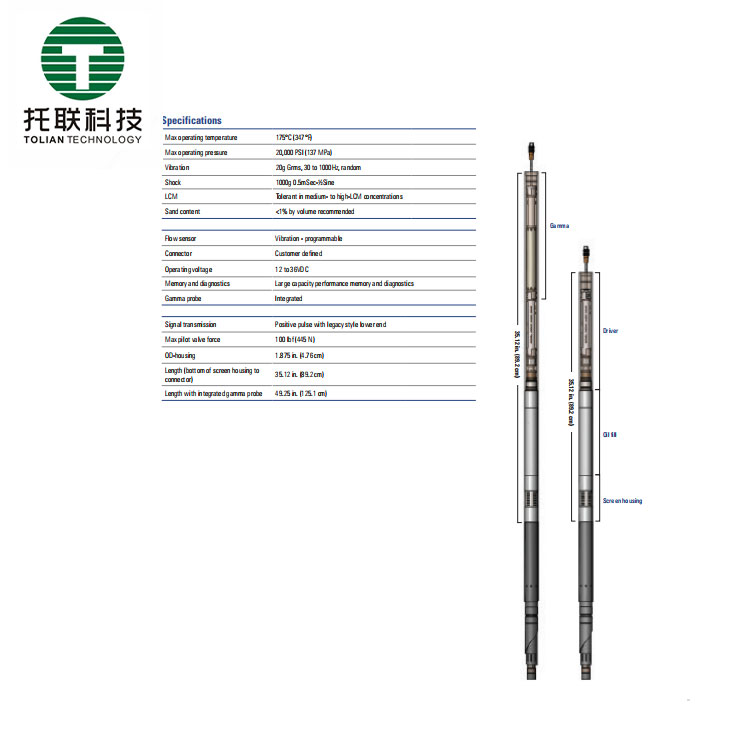

LWD Rotary Steerable System

The total length of the rotary steerable system (including power supply, pulser, MWD, logging system and rotary steerable system) is no more than 16 meters. Due to drill string vibration, impact, annular pressure, rotary steerable system could transmit real-time data. With azimuthal gamma-ray imaging function, rotary steerable system can be widely used in reservoir geosteering.

It also has the function of rotary steering and near bit well deviation measurement, and could control well trajectory accurately when drilling tool is continuously rotating. In rotary steerable system, automatic computing equipment on the ground sends commands during drilling to control downhole instrument, without occupying additional operation time. Rotary steerable system has several control modes: steering mode, stabilized mode and so on. Downhole closed loop controls system automatically.

Tool maintenance is easy. Steerable sub can be disassembled on site, so as to ensure the smooth field operations. Completing the equipment of drilling tools on site needs about 2 to 3 hours, which is fast and convenient.

Download

Company introduce:

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning,Milling ,boring and drilling | |

| CNC drilling deep hole and slender hole | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, gun drill, deep hole boring and driling machine, plano milling and boring machine |

| Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm | |

| CNC machining center range: four axis linkage | |

| Gun drill range: Dia3mm--12mm length: 3-5M | |

| Deep hole boring and drilling range: length:6m dia 200mm | |

| plano boring and milling range: stoke 2m*4m | |

| Cerificate | API ,ISO |

Hyper Cleaner

The hyper cleaner has the following functions:

1. Improve the carrying of debris. Carrying capacity of the mud on the sedimentary rock debris in the big stomach is improved, the formation of the rock debris bed is reduced and the migration efficiency of the cuttings is improved.

2. Reduce the probability of complex accidents in the underground. During the drilling of inclined or horizontal section, if there is large block falling, effective rolling can be carried out and small particles can be broken.

3. Improve drilling efficiency. The smooth flow of wellbore is improved, the lifting and lowering of drilling string are smoother, short trip time and well passing time are reduced. The mechanical drilling speed has been improved compared with conventional drilling, which improves production efficiency, shortens construction period and reduces construction risk.